On this site, we provide easy-to-understand explanations of the Kepner-Tregoe Method (KT Method) for those who want to learn it from scratch or those who know about it but struggle with its application or specific methods. We also include examples to help illustrate the concepts.

At the end, we present diagrams that serve as templates for thinking, making it recommended for those who want to visualize the overall picture.

Please make use of this in your daily business and management activities.

What is the Kepner-Tregoe Method?

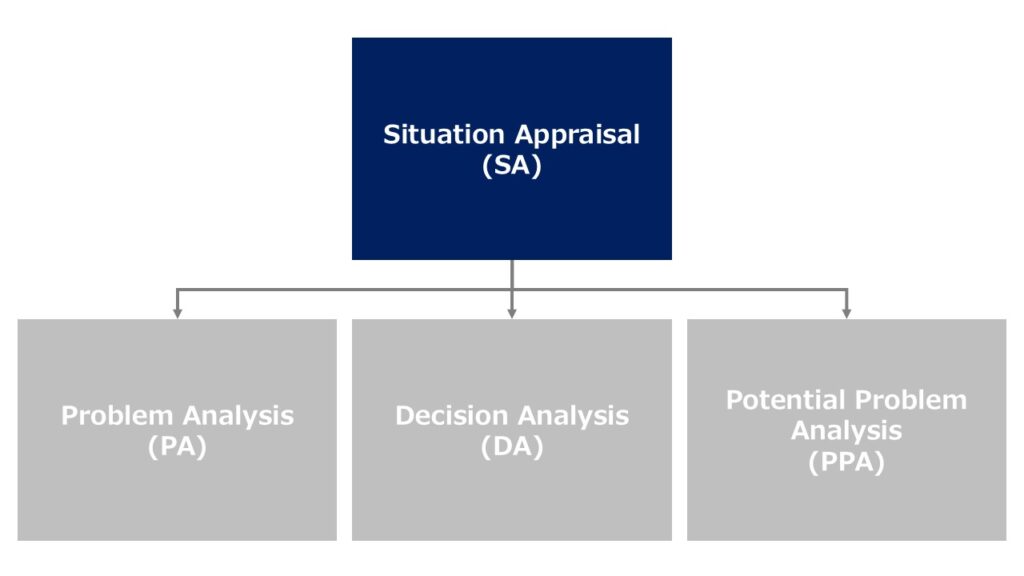

The KT Method, also known as the Kepner-Tregoe Method, is a business framework named after the initials of Charles Kepner, a social psychologist, and Benjamin Tregoe, a sociologist. It was introduced in their co-authored book “Rational Manager.” The KT Method is a framework for rational analysis and decision-making processes, enabling individuals to acquire decision-making skills. Although it was proposed over 50 years ago, it is still used in many corporate training programs today. The decision-making process is based on the following four thinking patterns

- Recognize the problem ; Situation Appraisal (SA)

- Break the problem into manageable parts ; Problem Analysis (PA)

- Determine priorities ; Decision Analysis (DA)

- Appropriately transition to the three analysis processes ; Potential Problem Analysis (PPA)

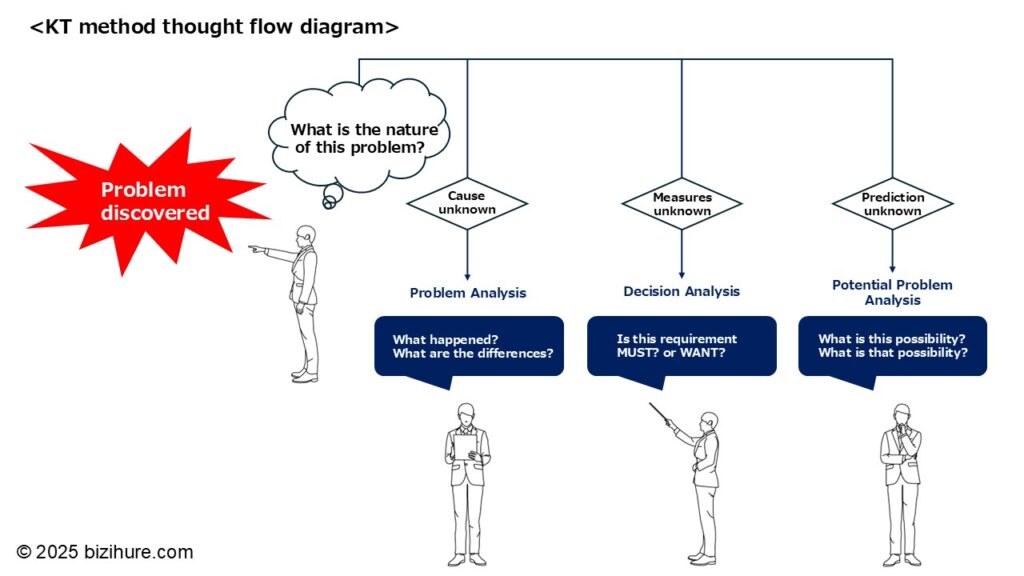

Appropriately transition to the three analysis processes is an important step in this process. As you can see from the diagram above, this process is positioned before the other three processes.

About “SA”, “PA”, “DA” and “PPA” in the KT Method

Now, let’s explain the four thinking patterns (methods) in detail.

1.Situation Appraisal (SA)

The first process of the thinking pattern (situation analysis and clarification) is understanding the current situation. As you can see from the diagram above, understanding the current situation is positioned differently from other processes. This process involves breaking down and organizing the situation or problem you are facing to understand it appropriately. Then, you prioritize the subdivided tasks. Usually, when a situation changes or a problem arises, various information surfaces. Some of this information is necessary, while some is not. Therefore, before taking any action, it is necessary to “sort out” the information obtained. Then, you need to prioritize the tasks to be addressed. After that, you move on to either problem analysis, decision analysis, or potential problem analysis, and actually implement solutions or countermeasures. In other words, you proceed through the following four steps sequentially:

- Recognize the problem

- Break the problem into manageable parts

- Determine priorities

- Appropriately transition to the three analysis processes

Appropriately transitioning to the three analysis processes is an important step in this process. As you can see from the diagram above, this process is positioned before the other three processes.

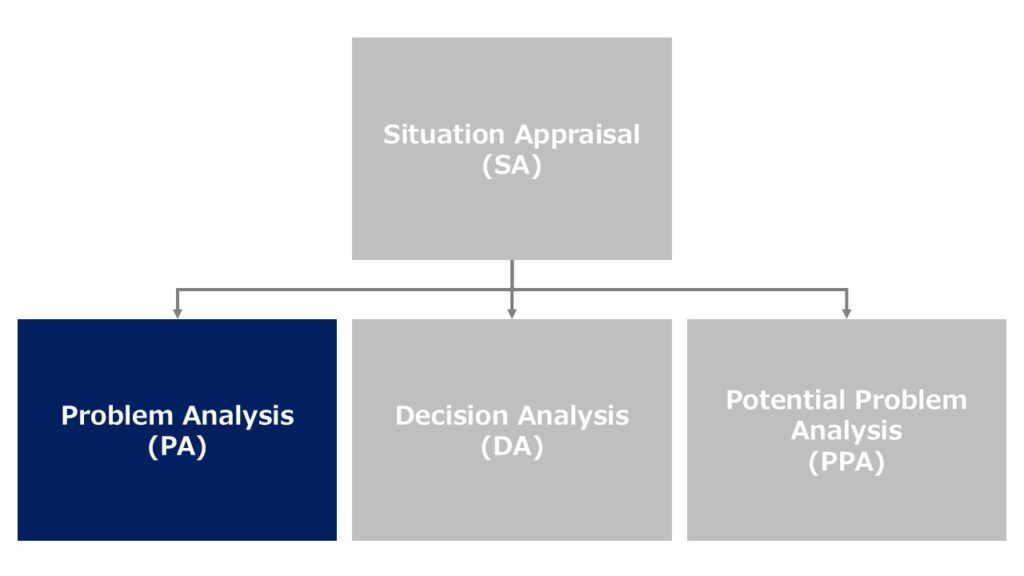

2.Problem Analysis (PA)

The second process of the thinking pattern (cause and effect) is problem analysis. This process involves accurately identifying and analyzing the current issues to find solutions. When a problem arises, you clarify what the problem is. This is called a “difference statement.” Then, you compare the actual problematic situation with the state before the issue occurred, and investigate and detail the differences, changes, and abnormalities. These detailed differences, changes, and abnormalities may be the factors of the problem, so you analyze each appropriately to identify the true cause. Next, to confirm the “evidence” of the identified cause, you trace back the changes that caused the problem and verify if they lead to the issue. As a result, you can identify the cause of the problem and then take measures to solve it. In other words, you proceed through the following four steps sequentially:

- Clarify what the problem is (difference statement)

- Detail the differences, changes, and abnormalities

- Compare the detailed differences, changes, and abnormalities with the factors

- Confirm the evidence of the most likely cause

After identifying the cause, you take essential evidence and confirm the “gray” as “black.”

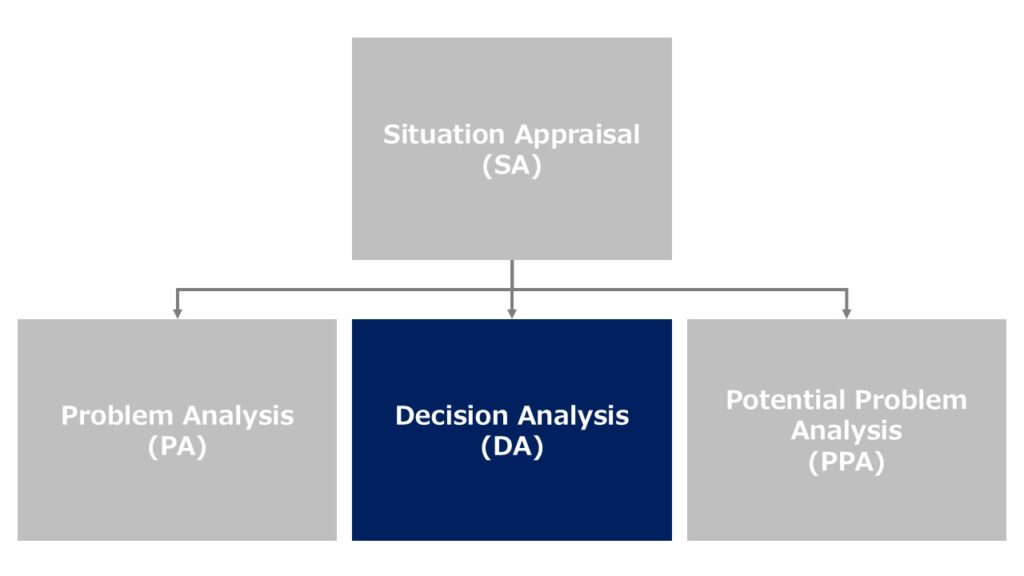

3.Decision Analysis (DA)

The third process of the thinking pattern (selection) is decision analysis. Initially, the following four elements are important items in decision analysis:

- Clarify what needs to be decided (decision statement).

- Goals for the decision [absolute goals (MUST) and desired goals (WANT)].

- Number of candidate options.

- Prediction of negative impacts.

Clarifying what needs to be decided means understanding why a new personnel evaluation system needs to be introduced when constructing it. Otherwise, it will simply end with determining the position classifications based on the seniority system. However, what you really want to improve might be a fundamental system change from the seniority system to a merit-based system. Therefore, the decision is to consider the introduction of a merit-based system. Thus, the “decision statement” needs to be clarified.

Next, regarding the goals for the decision, if the goal is absolutely non-negotiable, it becomes a MUST item, and if it is not an essential goal, it becomes a WANT item. However, even among non-essential items, there is a degree of importance, so it is necessary to set weights for each goal in the WANT items. This will be explained in the next section, “Examples of KT Method Utilization.”

The number of candidate options should be as many as possible. This is to prevent the decision from being overturned later, known as “flipping the table,” by eliminating any missing evaluation items.

Finally, the prediction of negative impacts on the decision items involves evaluating the items decided based on the current facts, considering the potential adverse effects that may occur in the future. This way, you can determine the optimal choice.

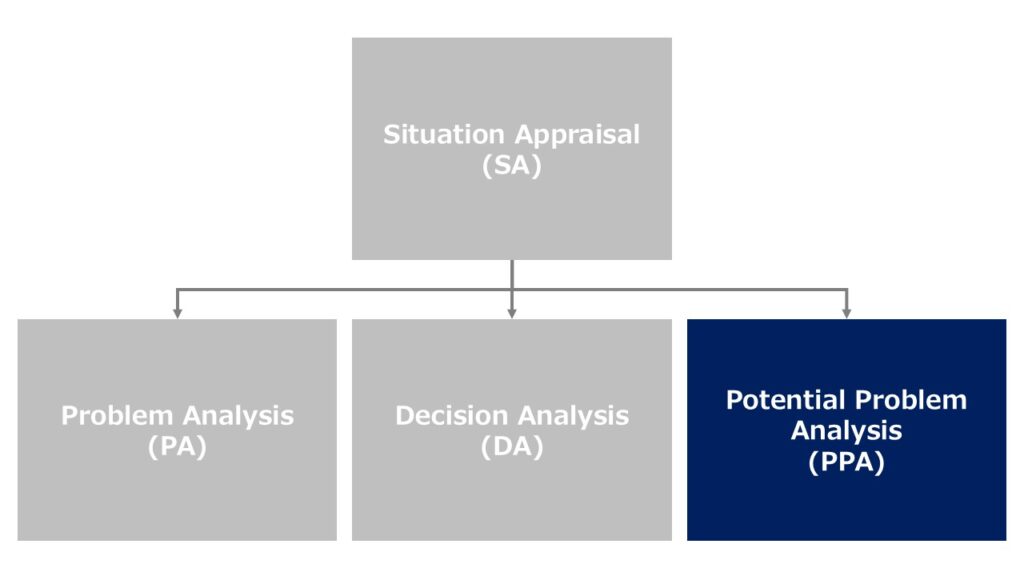

4.Potential Problem Analysis (PPA)

The fourth process of the thinking pattern (future prediction) is potential problem analysis. This process involves deciding on measures to prevent potential troubles in the future and measures to take after troubles have occurred. It is a predictive response, and while it may not necessarily happen, it is a measure to reduce the possibility, akin to “prevention is better than cure.” Additionally, even if measures are taken, it does not guarantee that troubles will not occur. There is a possibility that the measures may be insufficient, so it is necessary to consider secondary measures for situations that cannot be avoided. In other words, the items to be considered in potential problem analysis are as follows:

- Clarify the scope of risks to be covered.

- Extract specific potential problems that are anticipated.

- Implement preventive measures against potential problems.

- Understand that unexpected risks may also exist.

In potential problem analysis, since it involves anticipating possible risks and responding to them, it includes many uncertainties, unlike facts. Therefore, at this stage, it is necessary to understand that there may be unexpected risks, even if the specifics are unknown. By doing so, you can respond without causing major panic when encountering unforeseen risks.

How to use the KT method

Next, we will show how to utilize the KT Method.

Below, we explain the three analysis methods: “Problem Analysis: PA,” “Decision Analysis: DA,” and “Potential Problem Analysis: PPA” using examples. After that, we will explain the thinking behind “Situation Analysis: SA” based on these examples.

1.Situation Appraisal (SA)

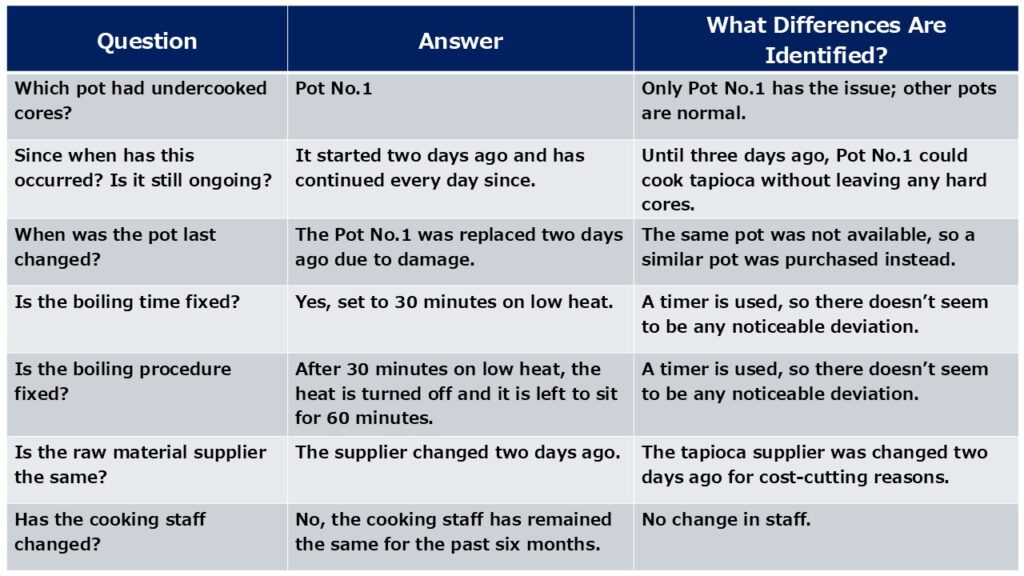

As an example, we showed an approach to the issue of tapioca cooked in the pot of machine No. 1 at a tapioca shop, where only the tapioca has a hard core.

Additionally, we follow the four steps below to proceed with problem analysis:

- Clarify what the problem is (difference statement)

- Detail the differences and abnormalities

- Compare the detailed differences and abnormalities with the factors

- Confirm the evidence of the most likely cause

Below is the table created for the analysis.

Here are the differences observed:

- Only the tapioca cooked in the pot of machine No. 1 has a hard core after boiling.

- The pot of machine No. 1 was replaced with a similar pot two days ago.

- The manufacturer of the tapioca raw material was changed.

From these observations, we focus on the differences in machine No. 1, as the issue is occurring only with this machine. The change in the tapioca raw material is common to other pots, and no abnormalities are observed in other pots, so we can conclude that the change in raw material is unlikely to be related to this issue. Therefore, the cause is the replacement of the pot in machine No. 1.

Next, we move on to step 4 for verification.

As a result of investigating the newly purchased pot, it was found that although the shape was similar, the material of the metal part, layer structure, and thickness were different. Additionally, it was confirmed that this pot has a faster heat dissipation rate compared to the previous pot, and the temperature after 60 minutes of standing in the “tapioca boiling process” was lower than that of other pots.

In conclusion, the difference in storage temperature during the cooking process due to the replacement of the pot is the cause.

2.Problem Analysis (PA)

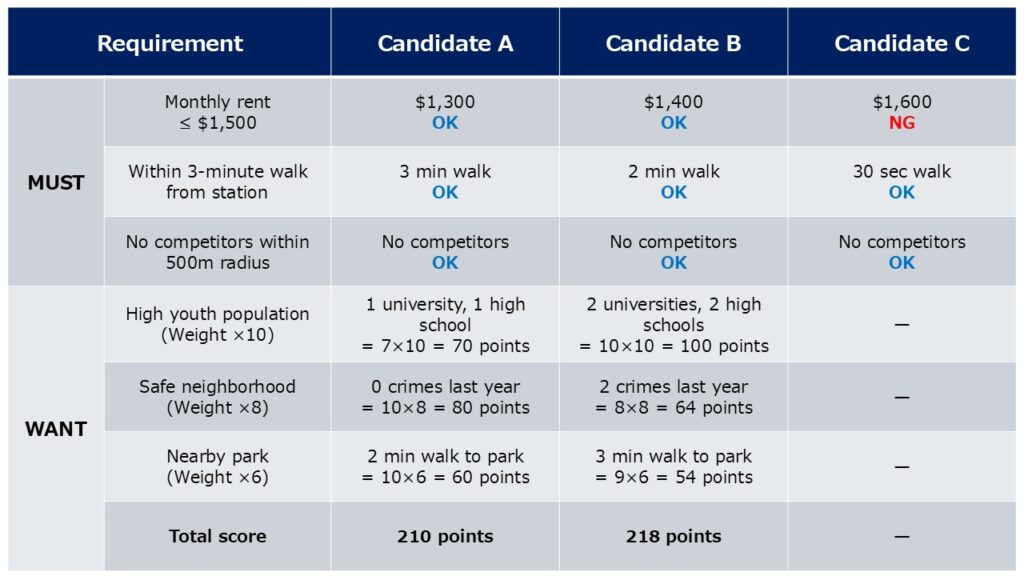

As an example, we decided on the location for opening a new tapioca shop as the decision statement. In this process, we extracted the desired items and analyzed how well each candidate location met these requirements. Based on this analysis, we determined the most suitable location from the candidate sites.

During this process, we created a decision analysis table (DA table) as shown below.

First, we determine the MUST requirements. In this example, the three non-negotiable MUST requirements are as follows:

- The rent must be $1,500 or less.

- The location must be within a 3-minute walk from the station.

- There must be no competing stores within a 500-meter radius.

In other words, any candidate location that does not meet even one of the above three requirements is excluded as a candidate location at that point. In this example, candidate location C is excluded because the rent is $1,600.

Next, we determine the WANT requirements. The WANT requirements are as follows, and we have set the weights as shown below:

- It would be nice if the population of young people is high… Weight: 10

- It would be nice if the security is good… Weight: 8

- It would be nice if there is a park nearby… Weight: 6

Then, we compare each candidate location against each requirement. At this time, we assign a maximum evaluation value of 10 points for each requirement, and the remaining are relative evaluation values. The value obtained by multiplying the evaluation value by the weight is the score of the candidate location for that requirement.

After that, we judge the candidate location based on the total value of each score. In this example, as shown in the table above, candidate location B is the appropriate location for opening the store.

In the final stage, we consider the future risks of candidate location B, and if we are confident that there are no problems, we make the decision.

3.Decision Analysis (DA)

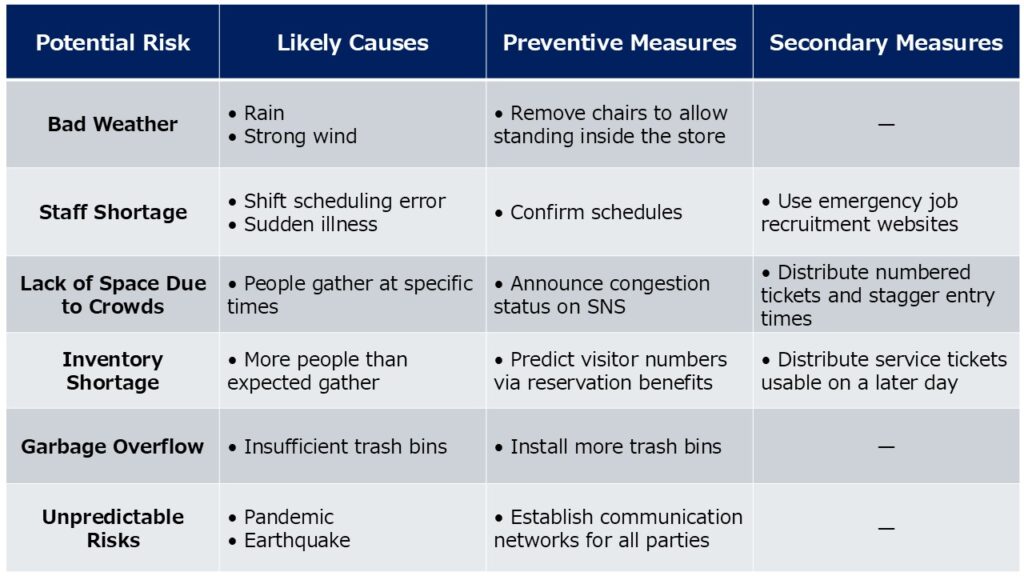

There are essential questions to consider when conducting potential problem analysis: “What risks are lurking?” and “What can be done about them?” I believe that the ability to predict potential problems heavily relies on past experiences. Just as James Webb Young suggested that “new ideas are combinations of existing ideas,” I think the method of prediction is similar. Therefore, prediction skills cannot be immediately put into practice just by learning the method. To make more accurate predictions, it is necessary to accumulate a lot of experience. Experience includes not only real-life experiences but also simulated experiences through books and other means.

Now, as an example for this section, we conducted a potential problem analysis for a tapioca shop (indoor store type) when holding an event. The results are shown below.

Next, we only need to take preventive measures for the event. For unpredictable risks, it is honestly impossible to make a complete prediction because we don’t know what will happen. However, if you have the mindset that unexpected things are bound to happen, you can respond calmly to a certain extent.

4.Potential Problem Analysis (PPA)

Finally, about understanding the current situation. Although the explanation is a bit out of order, this section on understanding the current situation serves as a step towards transitioning to the three analyses mentioned earlier. In this section, I will explain the concept behind it.

After an anomaly occurs, first understand the current situation, and then make the following judgments:

When you encounter a situation where the cause of the problem or discrepancy is unknown: -> Problem Analysis (PA)

When you need to decide on a standard, procedure, or method to proceed: -> Decision Analysis (DA)

When prediction is always necessary in problem analysis or decision analysis: -> Potential Problem Analysis (PPA)

Additionally, the problems that usually occur involve overlapping aspects of the three analyses.

Next, we only need to take preventive measures for the event. For unpredictable risks, it is honestly impossible to make a complete prediction because we don’t know what will happen.

However, if you have the mindset that unexpected things are bound to happen, you can respond calmly to a certain extent.

Summary of the Kepner-Tregoe method [Diagram]

The above is a diagram of the KT Method / Kepner-Tregoe Method.

This business framework is groundbreaking because it systematizes and shapes processes that are often carried out unconsciously. Once mastered, it can be utilized by anyone as a thinking framework. Of course, effectively using “Problem Analysis,” “Decision Analysis,” and “Potential Problem Analysis” requires experience, but once mastered, it becomes a utility skill that can be applied in various situations.

Especially, mastering Decision Analysis (DA) is recommended for management positions with frequent decision-making opportunities, as it leads to improved accuracy and speed in decision-making.