1. What is TRIZ?

TRIZ (pronounced “trees”) is a business framework for applying fundamental principles to the problem at hand and connecting it to solution-oriented, inventive thinking.

TRIZ was proposed by Genrich Altshuller as a systemized approach to invention in technical development. It categorizes solutions and inventive thinking into fundamental principles, making it a highly practical framework.

Altshuller worked in patent analysis and had the opportunity to examine many innovative technologies. Through this experience, he derived that there are certain principles and rules when inventing new technologies. Since this research was conducted after World War II, it is a theory with a long history.

By analyzing over 2.5 million patents, he constructed a method that allows people without special talents to solve problems using inventive thinking.

Incidentally, TRIZ is an acronym from the Russian “Teoriya Resheniya Izobretatelskikh Zadach,” which translates to “Theory of Inventive Problem Solving” (TIPS) in English.

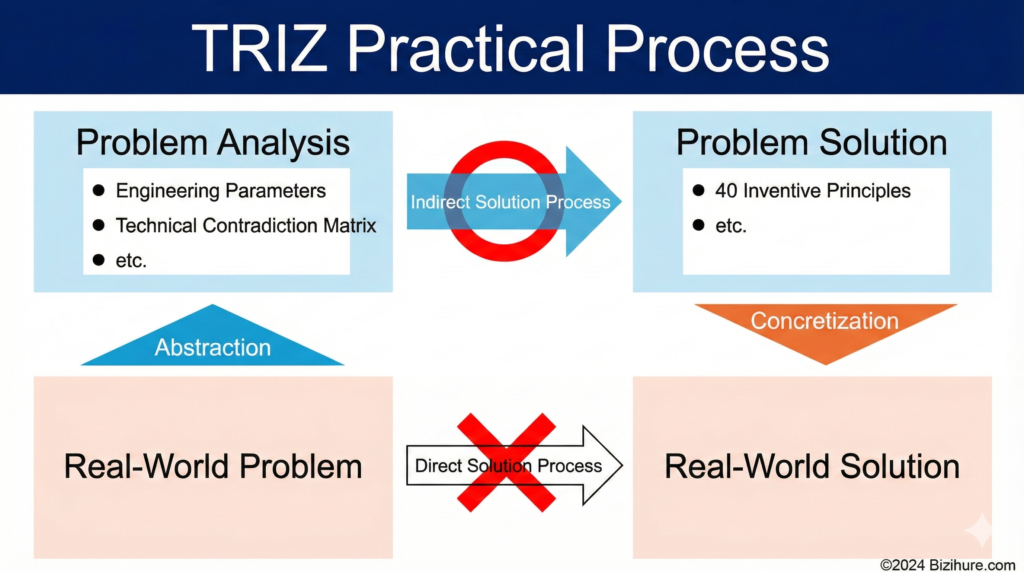

1. Overview of the TRIZ Practice Process

The process does not involve finding a direct solution to the problem at hand immediately. Instead, it follows these steps:

- Abstraction: Abstract the real-world problem.

- Analysis: Analyze the abstracted problem.

- Abstract Solution: Generate a solution for the abstracted problem.

- Concretization: Convert the abstract solution into a concrete real-world solution.

2. The 39 Engineering Parameters

To analyze the problem, TRIZ uses “39 Engineering Parameters.” Essentially, any problem can be classified (analyzed) into these parameters, which represent basic issues a system or object might have.

- Weight of moving object

- Weight of stationary object

- Length of moving object

- Length of stationary object

- Area of moving object

- Area of stationary object

- Volume of moving object

- Volume of stationary object

- Speed

- Force

- Stress or pressure

- Shape

- Stability of the object

- Strength

- Duration of action of moving object

- Duration of action of stationary object

- Temperature

- Illumination intensity

- Use of energy by moving object

- Use of energy by stationary object

- Power

- Loss of Energy

- Loss of substance

- Loss of Information

- Loss of Time

- Quantity of substance

- Reliability

- Measurement accuracy

- Manufacturing precision

- External harm affects the object

- Object-generated harmful factors

- Ease of manufacture

- Ease of operation

- Ease of repair

- Adaptability or versatility

- Device complexity

- Difficulty of detecting and measuring

- Extent of automation

- Productivity

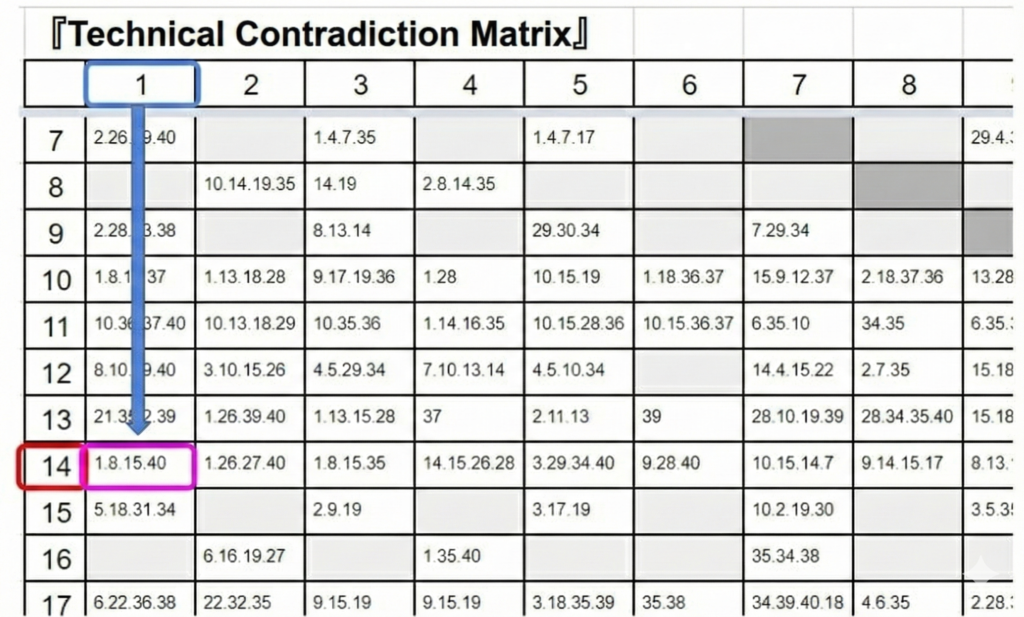

3. Technical Contradiction Matrix

When trying to improve one parameter, another parameter often gets worse (a trade-off). The Technical Contradiction Matrix maps these conflicts. The vertical axis represents the parameter you want to improve, and the horizontal axis represents the parameter that worsens. The intersecting cell provides the “Inventive Principles” suggested to resolve this contradiction.

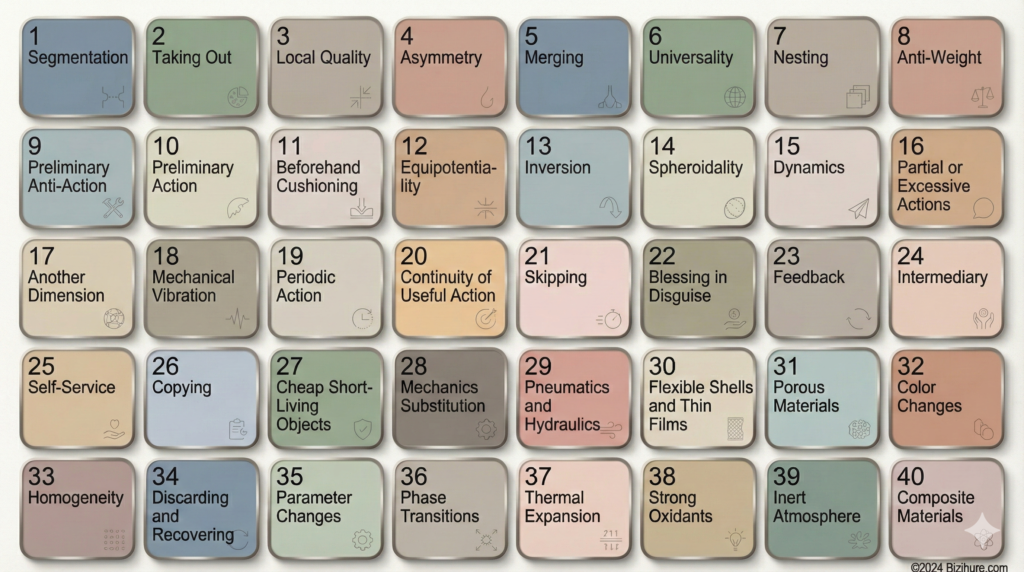

4. The 40 Inventive Principles

These are the 40 types of inventive thinking methods that lead to problem resolution, forming the core of TRIZ.

- Segmentation: Divide an object into independent parts; make an object easy to disassemble; increase the degree of fragmentation.

- Taking Out (Separation): Separate an interfering part or property from an object, or single out the only necessary part.

- Local Quality: Change an object’s structure from uniform to non-uniform; change an external environment from uniform to non-uniform; make each part of an object function in conditions most suitable for its operation.

- Asymmetry: Change the shape of an object from symmetrical to asymmetrical; increase the degree of asymmetry.

- Merging (Consolidation): Bring closer together (or merge) identical or similar objects or operations in space or time.

- Universality: Make a part or object perform multiple functions; eliminate the need for other parts.

- Nesting (Matryoshka): Place one object inside another, which is placed inside a third one.

- Anti-Weight (Counterweight): To compensate for the weight of an object, merge it with other objects that provide lift.

- Preliminary Anti-Action: If it will be necessary to do an action with both useful and harmful effects, this action should be replaced with anti-actions to control harmful effects.

- Preliminary Action: Perform the required change of an object (fully or partially) before it is needed.

- Beforehand Cushioning: Prepare emergency means beforehand to compensate for the relatively low reliability of an object.

- Equipotentiality: In a potential field, limit position changes (e.g., change operating conditions to eliminate the need to raise or lower an object).

- Inversion (The Other Way Round): Invert the action(s) used to solve the problem (e.g., make movable parts fixed, and fixed parts movable).

- Spheroidality (Curvature): Go from linear parts to curved parts, from flat surfaces to spherical surfaces. Use rollers, balls, spirals, domes.

- Dynamics: Allow characteristics of an object/system to change to be optimal at each stage of operation. If an object is rigid, make it movable or interchangeable.

- Partial or Excessive Actions: If 100% of an effect is hard to achieve, use “slightly less” or “slightly more” of the same method to simplify the problem.

- Another Dimension: Move an object in two- or three-dimensional space. Use a multi-story arrangement instead of a single-story one. Tilt or re-orient the object.

- Mechanical Vibration: Cause an object to oscillate or vibrate. Increase frequency (even to ultrasonic). Use piezoelectric vibrators.

- Periodic Action: Instead of continuous action, use periodic or pulsating actions. Change the periodic frequency.

- Continuity of Useful Action: Carry on work continuously; make all parts of an object work at full load, all the time. Eliminate idle or intermittent actions.

- Skipping (Rushing Through): Conduct a process, or certain stages (e.g., destructible, harmful, or hazardous operations) at high speed.

- Blessing in Disguise: Use harmful factors (particularly environmental) to achieve a positive effect. Eliminate the primary harmful action by adding it to another harmful action to resolve the problem.

- Feedback: Introduce feedback (referring back, cross-checking) to improve a process or action.

- Intermediary: Use an intermediary carrier article or intermediary process. Merge one object temporarily with another (which can be easily removed).

- Self-Service: Make an object serve itself by performing auxiliary helpful functions. Use waste resources or energy.

- Copying: Instead of an unavailable, expensive, fragile object, use simpler and inexpensive copies.

- Cheap Short-Living Objects: Replace an expensive object with a multiple of inexpensive objects, compromising certain qualities (such as service life).

- Mechanics Substitution: Replace a mechanical means with a sensory (optical, acoustic, taste or smell) means. Use electric, magnetic, or electromagnetic fields to interact with the object.

- Pneumatics and Hydraulics: Use gas and liquid parts of an object instead of solid parts (e.g., inflatable, filled with liquids, air cushion, hydrostatic).

- Flexible Shells and Thin Films: Use flexible shells and thin films instead of three-dimensional structures. Isolate the object from the external environment using flexible shells and thin films.

- Porous Materials: Make an object porous or add porous elements (inserts, coatings, etc.).

- Color Changes: Change the color of an object or its external environment. Change the transparency of an object or its external environment.

- Homogeneity: Make objects interacting with a given object of the same material (or material with identical properties).

- Discarding and Recovering: Make portions of an object that have fulfilled their functions go away (discard by dissolving, evaporating, etc.) or modify these directly during operation.

- Parameter Changes: Change an object’s physical state (e.g., to a gas, liquid, or solid). Change the concentration or consistency. Change the degree of flexibility. change the temperature.

- Phase Transitions: Use phenomena occurring during phase transitions (e.g., volume changes, loss or absorption of heat).

- Thermal Expansion: Use the thermal expansion (or contraction) of materials.

- Strong Oxidants: Replace common air with oxygen-enriched air. Replace enriched air with pure oxygen. Expose air or oxygen to ionizing radiation. Use ozonized oxygen.

- Inert Atmosphere: Replace a normal environment with an inert one. Add neutral parts or inert additives to an object.

- Composite Materials: Change from uniform to composite (multiple) materials.

2. Example of using the TRIZ Contradiction Matrix

Example: You want to improve the strength of a container because it is weak.

- Improvement Parameter: 14 (Strength)

- Worsening Parameter: Simply making the material thicker/stronger might increase the weight. So, Parameter 1 (Weight) becomes the negative trade-off.

By looking at the intersection of Parameter 14 (Strength) and Parameter 1 (Weight) in the matrix, specific principles are suggested:

- Principles: 1, 8, 15, 40.

- (Segmentation, Anti-Weight, Dynamics, Composite Materials)

Using these principles helps find a solution (e.g., using “Composite Materials” like carbon fiber to increase strength without increasing weight) rather than just relying on intuition.

3. Summary of TRIZ

TRIZ requires some practice to understand but offers a robust framework. There are other methods like Substance-Field Analysis and the 9-Screen Method that complement TRIZ.